Custom badges, also called custom patches, have been popular for personal and professional purposes for many years. And there is no sign of their popularity slowing down. They can be produced through various styles and methods – the most popular being Embroidered, sublimation and woven badges. But which ones are right for your design?

There are various considerations that you must address when making your decision. Is the method capable of producing the design you’d like? Is it affordable? How durable is it? – to name a few. This post will explain choices in detail and help you decide the right method for your custom badge. Embroidered vs woven patches?

We’ll cover the following:

- What are Custom Embroidered Badges?

- What are Custom Woven Badges?

- What are Custom Sublimation Badges?

- The Pros and Cons of Embroidered Badges

- The Pros and Cons of Woven Badges

- The Pros and Cons of Sublimation Badges

- Embroidered vs Woven: A Comparison

What are Embroidered Custom Patches?

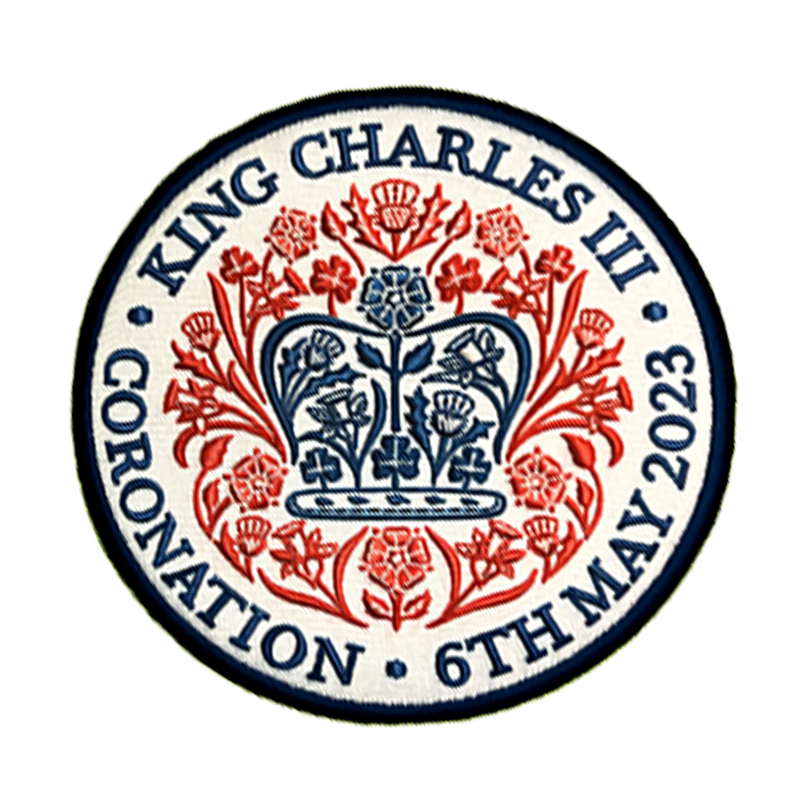

There are several ways to approach this technique to bring the best out of your logo and designs. An embroidered patch is produced onto a base cloth by a stitching process. The result is a textured and raised design effect. The regal finish is favoured by many as it connotes a well-established brand and is a tidy professional look.

Embroidered logos are integral to uniforms and team wear worldwide, never mind just in the UK. With an embroidered badge, you have the choice of using 100 percent embroidery or letting the base cloth show through. The base cloth is usually twill or felt.

What are Custom Woven Patches?

Woven badges are two prominent sets of threads interlaced to form a surface that illustrates your design. They’re a useful option to achieve photorealism in your designs. Human or animal faces, landscapes, cars or motorcycles, and brilliant shading and gradients are all popular examples of what can be replicated on small woven custom badges.

You never have to worry about the embroidery percentage or thread count, as the threads are woven together and not sewn onto a felt or twill base. Please think of how digital images are combined with dots, similar to how woven badges are produced. The result is a durable, intricately designed and strikingly coloured badge that you’ll most certainly be proud to boast.

What are Custom Sublimation Patches?

Custom sublimation patches are decorative emblems or badges that often embellish clothing, bags, or other fabric items. These patches utilize sublimation printing, a specialized process involving heat and pressure to transfer dye onto the fabric or material. The sublimation process enables high-resolution, full-colour designs to imprint on the surface, resulting in vibrant, long-lasting patches that resist fading and wear over time.

Custom sublimation patches offer numerous advantages over traditional embroidery or screen-printed patches. They allow for greater design flexibility, as intricate details and an unlimited colour palette can be easily reproduced. Additionally, sublimation patches are lightweight and lay flat on the fabric, providing a smooth and polished appearance. As the design is permanently embedded into the material, these patches are highly durable and can withstand washing, ironing, and exposure to sunlight without fading or peeling. With the ability to create unique, high-quality, and long-lasting patches, custom sublimation patches are an excellent choice for businesses, organizations, and individuals seeking a stylish and personalized way to showcase their identity or message.

The Pros and Cons of Custom Embroidered Badges

When choosing your custom badge, the methods you can opt for are more suited to some jobs than others. Different methods excel in different areas and can offer value uniquely – and embroidery is no different.

Pros

- Embroidery badges can produce a lot of depth. The raised effect and ability to add more borders make it possible to have a closer to 3D effect on designs, which is brilliant for company logos and slogans on workwear, for example.

- The logo has an added texture due to the different motifs and stitching techniques that can be used.

- There’s a reason why embroidery has been around for so long. Finish quality and durability undeniably make embroidery one of the most popular choices when personalizing products.

- The colour payoff is richer than other types of badges. This is due to the ability to select a range of threads from soft pastel colours to attention-grabbing neons, guaranteed to make your custom badges stand out.

- The turnaround time for embroidery orders is usually pretty fast. So, you can show off your new band merchandise patches or your business’ staff uniform in no time. Plus, whilst the turnaround is so quick, there’s no compromise in quality on your badges.

Cons

- If it’s extreme detail that you’re looking for, then embroidery won’t be the preferred choice. Intricate patterns or finicky designs are limited as embroidery machines can’t usually produce what other methods can. If you choose to go ahead with embroidery despite having a detailed design, the finish won’t be as good as you’d like.

- With embroidery, you can’t blend the colours. Stitching is brought together as block colours, unlike in woven custom badges, where the colours are intertwined and blended together smoothly. So, if your design has any shading, blending or gradients, it won’t translate well on the finished badge.

- Just as the intricacy of the design is limited, so is font size. Unfortunately, small text is unavailable as the results are poor if you go below a certain size.

The Pros and Cons of Custom Woven Patches

Like embroidery, the woven method is more suited to particular jobs than others. Woven badges are common everyday items that we use. For example, staff uniforms, team wear and even fashionable clothing adopt the badge style. So let’s see the difference between embroidered vs woven patches.

Pros

- Woven badges have a nicer feel overall. They are softer to the touch and more comfortable. Because they’re more aesthetically pleasing, it gives the whole garment, not just the patch, a more quality feel.

- These badges can accommodate a lot of small details. This gives you room to involve more intricate designs in your logo. This gives off an incredibly impressive finish. If a business can impress potential customers with its logos and badges, it gives the impression of a well-established and professional business.

- The text size of a woven badge can be as small as 1.2 mm.

- These types of badges are especially light.

- Since the production is entirely different from embroidery badges, the end result is extremely flat, providing uniformity throughout the design.

- You can use heat seal backings for woven badges making for an extremely simple and easy application method.

Cons

- These badges take 2-3 weeks to be delivered, which can be a hindrance if you need a quick turnaround time or place a last-minute order.

- Because of their uniqueness, the price point for woven badges is higher, especially for smaller volumes.

- Due to the nature of weaving, sometimes there must be a 1-2 mm tolerance in the border.

The Pros and Cons of Custom Sublimation Badges

So in this battle of embroidered vs woven patches or sublimation patches, all are great contenders. But we must know the advantages and disadvantages of each!

Pros

- High-resolution, full-colour designs: Sublimation allows for intricate, detailed designs and unlimited colours, resulting in vibrant, eye-catching badges.

- Durability: The sublimation process creates a permanent bond between the ink and the material, making the badges resistant to fading, peeling, and wear over time.

- Smooth and lightweight: Sublimation badges lay flat on the fabric, providing a polished appearance without adding significant weight or bulk to the item.

- Design flexibility: Sublimation can reproduce complex designs, including gradients and photographic images, that may be difficult or impossible to achieve with traditional embroidery or screen-printing techniques.

- Eco-friendly: The sublimation process may use water-based inks free from heavy metals, formaldehyde, and other harmful substances, making it an environmentally friendly option.

Cons

- Limited substrate options: Sublimation works best with polyester or polyester-blend materials, which may not be ideal for all applications or preferences.

- Higher initial costs: The equipment and materials required for sublimation printing can be more expensive than traditional embroidery or screen-printing methods, potentially leading to higher initial costs.

- Incompatibility with some fabrics: Sublimation may not be suitable for all fabrics or materials, particularly those with low polyester content or high heat sensitivity.

- Colour matching challenges: While sublimation offers a wide range of colours, exact colour matching can be difficult due to variations in substrates, inks, and printing conditions.

- Reduced vibrancy on dark materials: Sublimation badges may appear less vibrant on darker fabrics, as the process relies on transparent inks that do not contain white. This can make achieving the desired visual impact on dark-coloured substrates challenging.

Embroidered vs Woven vs Sublimation Patches: A Comparison

| Badge Type | Cost | Production Time | Size/Weight | Detail | Border Tolerance | MOQ | Comparison |

|---|---|---|---|---|---|---|---|

| Embroidery | Cost-effective at lower quantities | Quicker production (1-2 weeks) | Bulkier and heavier | Limited amount of detail | Matches Closely | 25pcs | Authentic/traditional feel |

| Woven | Comparatively expensive at lower quantities | Take longer to produce (2-3 weeks) | Slimmer/more uniform | Almost double the amount of detail | 1-2 mm tolerance | 100pcs | Closer to printed |

| Sublimation | Cost-effective for smaller quantities | Fastest production time (7 days) | Slimmer/more uniform | Unlimited detail | Matches Closely | 25pcs | Best for intricate designs with a lot of detail |

Woven Patches

As you can see, these are front and back pictures of a woven badge. You can see everything. The text is coherent, the building is much clearer, and you can see the tiny details of the crest at the bottom. The badge is also laser cut into a specific shape with a heat seal backing. Click here for the video!

Embroidered Badges

Here we have front and back pictures of an embroidered badge. It has a vintage and classic feel; the raised 3D effect looks nice on the logo, and the bold text adds depth and heft to the design. Click here for the video.

Sublimation and Sublistitch Badges

Sublimation badges are a type of printed badge with vibrant colours and high-quality resolution.

Sublistitch badges mimic embroidery’s look but are printed using a special technique. Both are excellent options for achieving intricate designs with fine detail. Please click here for a short video comparison.

You cannot categorise some designs into a specific badge type. The logo is too beautiful to be made flat as a woven badge, and the small text is too tiny to be legible in an embroidered one. For these dilemmas and to give our customers room for further creativity, the best option is a combination type badge where you can combine the woven or sublimation badges with embroidery.

The market for embroidered badges has always been larger than the woven badges market since embroidered badges have existed way longer than woven badges, many businesses and hobbyists already possess all the mechanics and skills required to create the former.

The popularity of woven badges is evolving and growing. Businesses understand the advantages of choosing woven badges over embroidered and direct embroidery.

But sublimation badges are quickly becoming popular for promotional companies, smaller teams, and clubs.

In the UK, professional football leagues have shifted from traditional embroidered to woven badges, which have become a staple for team wear and gear. This shift has been notable as direct embroidery and badges were previously the norms in football.

However, In the mid-2010s, we saw a change being implemented throughout the country’s team wear and merchandise; woven badges. Clubs and sportswear brands have switched to a newer, slimmer and more comfortable member of the badge family. Similarly, with the advancement in printing techniques, sublimation badges are the new Go to badge for promotional companies who want a quick turnaround.

Make Sure You Get the Right Type For Your Custom Badges

At Embroiderybadge.uk, we’re dedicated to ensuring you get the right product that meets your every need. We’ve got you covered from helping you design your logo and creations to ensuring you’re utilizing the right technique.

Don’t miss a thing with our regular email newsletter. Be the first to find out about any industry news, handy tips and advice, plus cool personalization inspiration and sign up today. So the choice is yours! Embroidered vs woven patches? Woven vs Sublimation patches? What will you pick?

[maxbutton id=”1″ url=”orders.embroiderybadge.uk” text=”Place a Free Quote” ]